.png.transform/rendition-xs/image_image%20(1).png)

Pan de Cruz de Ciudad Real PGI

A compact and dense loaf of bread made from wheat flour, with a consistent white crumb and a smooth crust, in the form of a rounded bulging loaf. Two perpendicular cuts are made deep into the top of the crust in the shape of a cross, which gives the bread its name.

Tasting notes

It is round and flat, with a crust. It has a thick crust of between one and two millimeters, which is smooth and crisp, golden to light brown in color and tasting of toasted cereal. The crumb of the bread is white, with a smooth, spongy and consistent texture; it has no alveoles and looks like cotton. The crumb has an intense cereal aroma with a pleasant and slightly sweet taste; the crust is smooth and crisp and tastes of toasted cereal.

Other notes

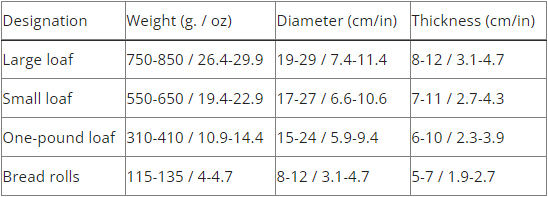

This bread is obtained from a hard dough made from wheat flour. Under normal storage conditions, this bread stays fit for consumption for 6 or 7 days. The product has no mould, abnormal residue or any kind of foreign matter. The maximum moisture content of the crumb is 30% and the acidity of the loaves is between pH 5 and 7. The designation of the loaves, with their weights and sizes, is as follows:

Production / Processing method

- Mixing: Being a hard dough, it can only be mixed using a mechanical dough mixer, for as much time as is needed to obtain a homogenous dough. Mixing time is between 20 and 30 minutes, depending on the type of machine used, ensuring that the dough does leave the machine at a temperature above 24-25 ºC / 75.2 -77º F.

- Refining or kneading: The dough is placed in a kneading machine, preferably one with slats, and put through the machine several times until a thin, elastic dough is obtained, with no lumps to the touch, and that can be rolled out very thinly without breaking.

- Weighing: As a handmade bread, it is weighed using a volumetric measuring device, electronic scales or a volume divider.

- Shaping: Shaping is also done by hand. Once the dough has been weighed, the shaping process involves making the piece of dough into a rounded conical shape using the hands, ensuring no residue sticks to it. It is then flattened into a circle and stretched. This makes the circle bigger by thinning the edges while ensuring the centre remains taller.

- Rising: Once the bread is shaped, it is placed on a board covered with linen or a similar fabric. Rising usually takes place at room temperature, so that a thin crust forms on the bread, so it does not need much heat. The correct conditions in the rising room are a temperature of between 26 and 30º C / 78.8 and 86º F and a relative air humidity of 40 and 45%. Rising time varies between 1 hour 20 minutes and 2 hours 20 minutes, depending on the room temperature.

- Cutting: Cutting is also done by hand. Once the bread has risen, two perpendicular cuts are made in the top of the loaf in the shape of a cross. In one of the quarters made by the cross, the loaf is marked with the code corresponding to the registration number of the bakery that baked the bread, using a metal stamping tool made specifically for this purpose. The bread is then left to rest for 10 to 15 minutes to allow the cut to take shape as the crust forms. At this stage, the underside of the bread is marked with the Protected Geographical Indication Pan de Cruz de Ciudad Real symbol, consisting of the Calatrava Cross, made using small holes in the crust, using a special tool with spikes in the form of the PGI logo, which also serves to prevent the crumb coming away from the crust during the baking process.

Placing in the oven: This stage is also done by hand, starting with taking the loaf that has already been cut on the top and placing it in the oven using a paddle, with the code corresponding to the registration number of the bakery and the perpendicular cross-shaped cuts facing downwards.

- Cooking or baking: This bread is baked in ovens equipped with heat-reflecting bottoms and walls. Total cooking time is between 30 and 50 minutes. The oven temperature must be 250º C / 482 º F for the first 15 minutes and then reduced to 200º C / 392º F for the remaining 15 to 35 minutes.

- Removal from the oven: The bread is removed from the oven using the same paddle and placed on trolleys with wooden shelves for airing and cooling. Once cooled, the loaves are labeled by hand and are ready for distribution.

Geography / Relief and climate

The essential features that link the product to the geographical area are related primarily to the region's environmental characteristics. The climate conditions in the area, characterized by low relative air humidity, has had a considerable influence on the final shape and appearance of the loaves, as they were consumed over a long period of time and so had to last, as well as on their preparation and distinctive taste. The low relative humidity of the air is the reason for the crumb's dense but cotton-like consistency and no alveoles, and its characteristic smoothness.

Regulatory Council

Consejo Regulador IGP Pan de Cruz de Ciudad Real

Asociación Provincial de Panaderías y Pastelerías de Ciudad Real

Avda. Rey Santo,8. 2ª Planta (Edificio Europa)

13001 Ciudad Real

Castilla-La Mancha

Tel: (+34) 926 600 002 / 699 086 399

ipg@afexpan.es

Sources:

- Spanish Ministry of Agriculture

Under normal storage conditions, this bread stays fit for consumption for 6 or 7 days.

- Pan de Cruz de Ciudad Real 1

- Pan de Cruz de Ciudad Real 2

Ciudad Real (Castile-La Mancha)